Production

Jean-Paul Luthy, photographer, Switzerland

All our watches are produced in Bienne. Every model has an entirely Swiss made quartz movement from the manufacturer ETA. We use a unique goldplated finish, with jewels and batteries of highest quality.

Pierre Junod Watches can readily supply replacement leather straps and spare parts for most models for at least 15 years after a design has been introduced.

Responsibility

“This is our manifesto for a more ecological and responsible production process and, in a small way, a cleaner world”

Pierre Junod

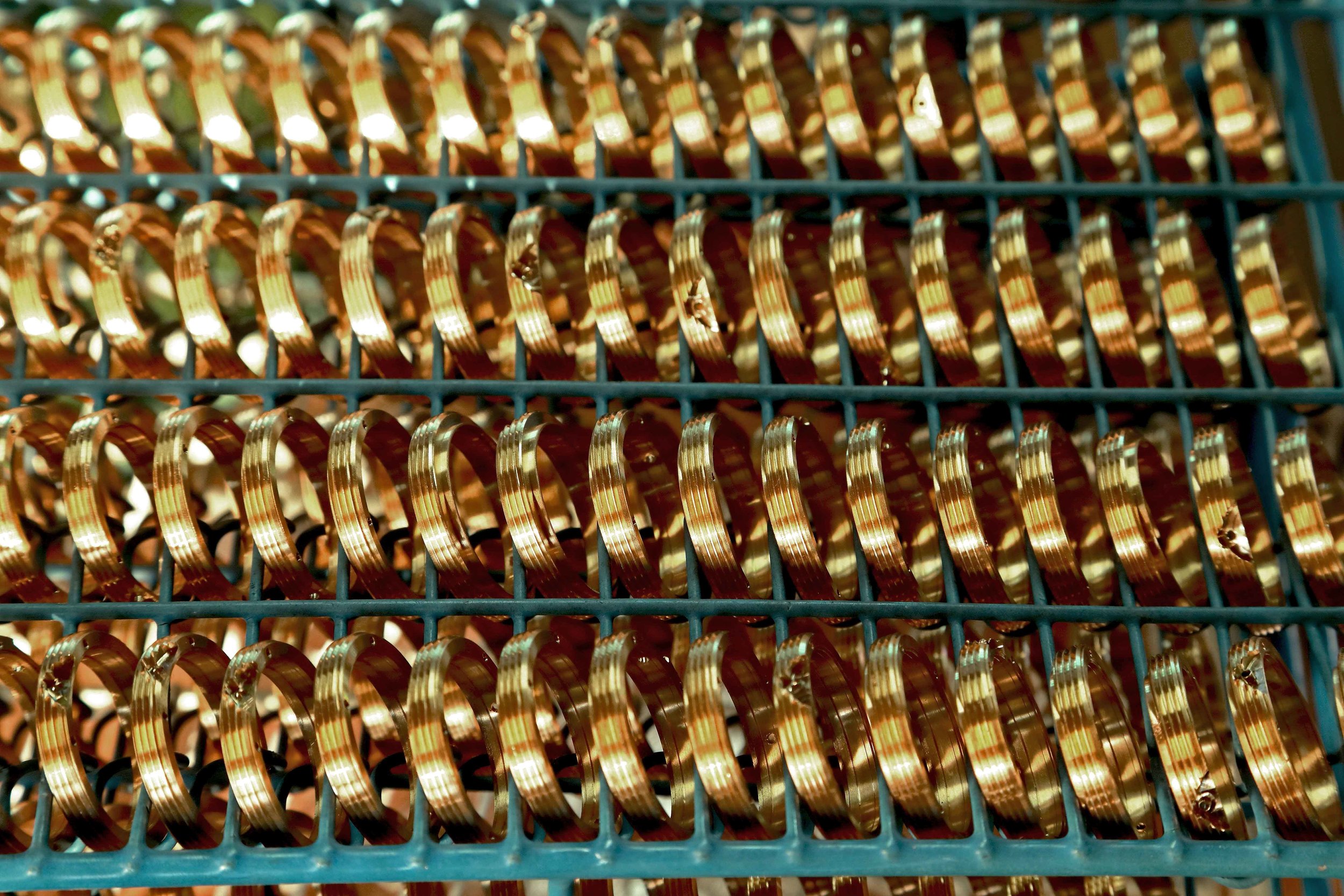

Our movements

We use only gold plated, swiss made ETA quartz movements.

They meet European Union directive ROHS II which limits the use of lead, mercury, cadmium, hexavalent chromium, polybrominate biphenyls (PBB) and polybrominate diphenyl ethers (PBDE) in electric and electronic devices in the European market from 3rd January 2013. These movements also meet the requirements of the RoHS directive.

Quartz - How does it work?

In 1880, the Curie brothers discovered that some materials vibrate when an electric current is passed through them, a phenomenon known as piezoelectricity. Quartz crystal, which is a silicon dioxide, provides the best stability/machinability/price for timekeeping. The current standard frequency for these vibrations in 32,768 Hz. They are counted by a processor, which acts as a master clock. The processor then proceeds to divide this frequency to derive the second. In case of analogue watches a system of micro-motors operates the hands, powered by the same battery that makes the crystal vibrate.

Our leather straps

All of our leather straps are “eco-produced.” This means that they are tanned without using chrome or chemical additives.

The leather is coloured, using only organic extracts from various plants and woods.

We only use leather straps that are made in Europe and produced in this way.

Our batteries

Our batteries are 100 % Swiss made.

They contain no mercury and are also lithium free.

Our packaging

Our packaging is made from recycled cardboard and is produced entirely in Switzerland.

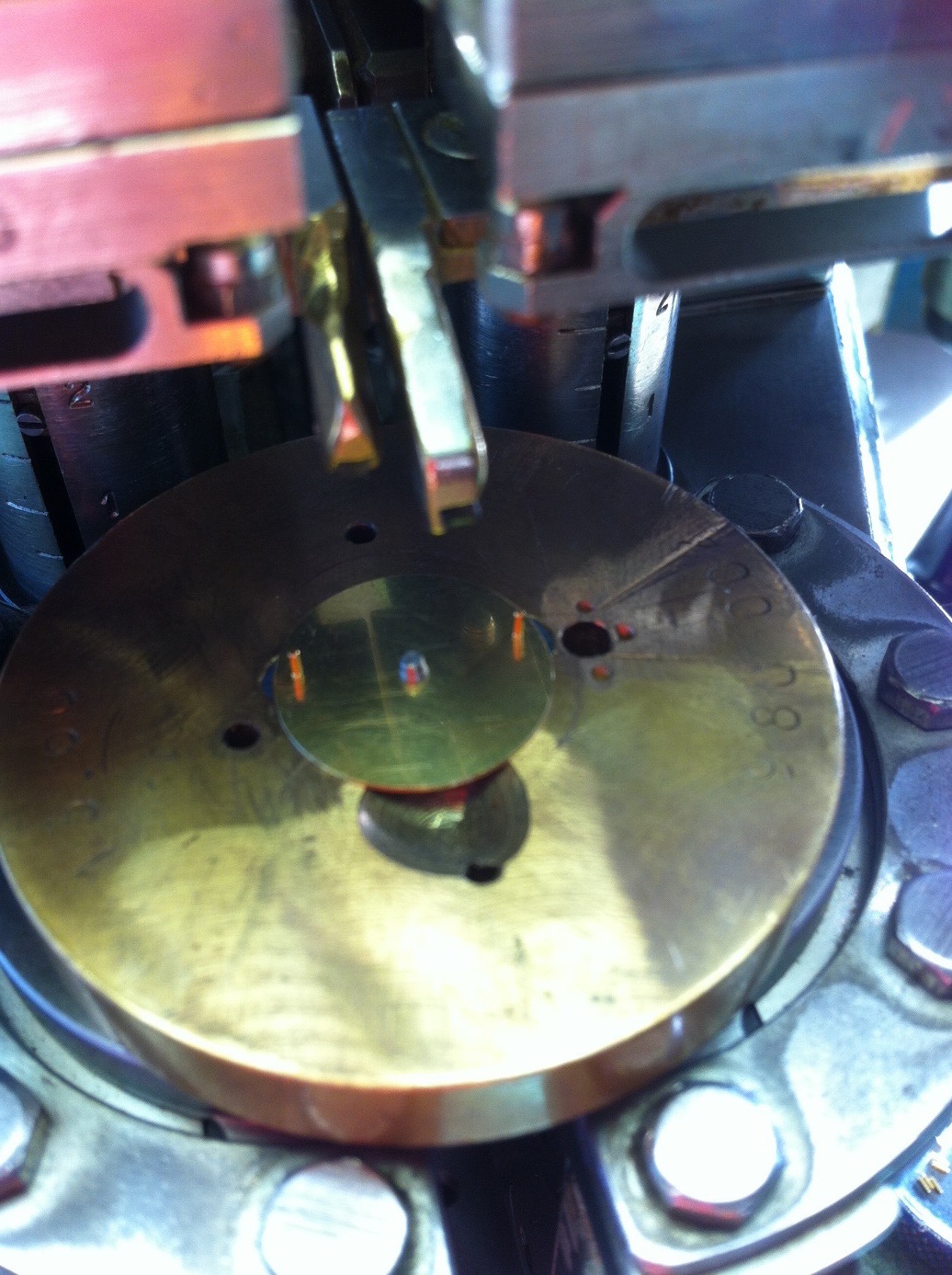

Assembly

Danuta assembling watches in workshop in Bienne

All our watches are assembled in our own workshop in Bienne, Switzerland. 90 % of the parts (mecanism, face, hands, steel cases, engravings and packaging) are produced within 40 km of our workshop and many are produced within only 3 km.